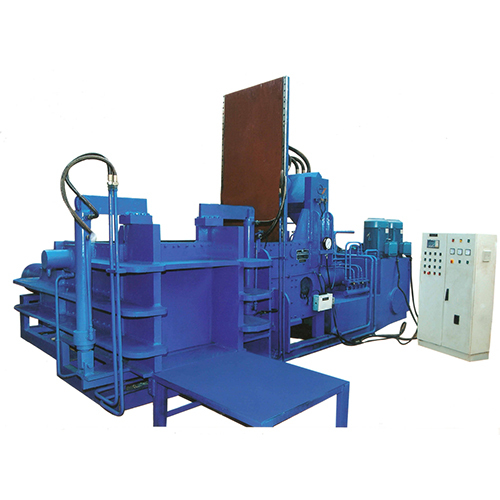

Triple Compression Baling Press

Price 1500000.0 INR/ Unit

MOQ : 1 Unit

Triple Compression Baling Press Specification

- Usage

- Industrial

- Power Source

- Hydraulic

- Condition

- New

- Product Type

- Triple Compression Baling Press

- Weight

- 5000 Kilograms (kg)

- Voltage

- 220-240 Volt (v)

- Color

- Blue

- Motor

- 30HP

- PLC System

- YES

- Solenoid Valve

- YES

- Pressure Gauge

- 2500PSI

Triple Compression Baling Press Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- DELHI

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 5 Units Per Month

- Delivery Time

- 1 Months

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Asia

- Main Domestic Market

- All India

About Triple Compression Baling Press

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

More Products in Triple Compression Baling Press Category

Triple Compression Hydraulic Baling Press

Price 1800000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Source : Hydraulic

Voltage : 220240 Volt (v)

Color : Blue

Triple Compression Baling Press With Turn Out Scrap Metal Baler

Price 1500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Source : Hydraulic

Voltage : 380440 Volt (v)

Color : Blue Paint Coated

Hydraulic Metal Baler Press Machine

Price 1500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Source : Hydraulic

Voltage : 415 Volt (v)

Color : Blue Painted

Hydraulic Metal Baler Press with PLC Control

Price 1800000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Power Source : Hydraulic

Voltage : 415 Volt (v)

Color : Blue Paint Coated

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free