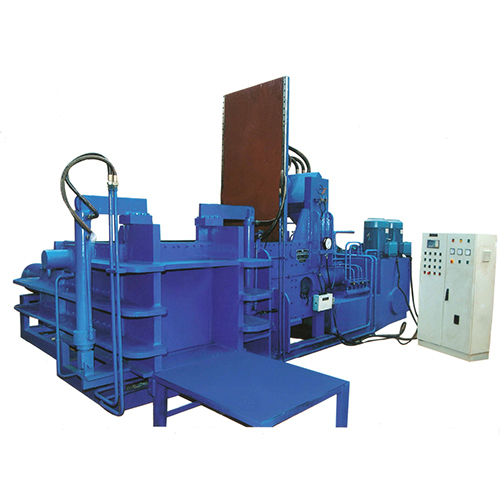

Robust Construction Triple Compression Hydraulic Baling Press

Price 1800000.0 INR/ Unit

Robust Construction Triple Compression Hydraulic Baling Press Specification

- Usage

- Industrial

- Power Source

- Hydraulic

- Size

- Standard

- Condition

- New

- Product Type

- HORIZONTAL

- Weight

- 6500 Kilograms (kg)

- Color

- Blue

- Voltage

- 220-240 Volt (v)

- Motor

- 30

- Solenoid Valve

- YES

- Pressure Gauge

- 2500 PSI

Robust Construction Triple Compression Hydraulic Baling Press Trade Information

- Minimum Order Quantity

- 1 Unit

- FOB Port

- delhi

- Payment Terms

- Cash Advance (CA), Cash in Advance (CID)

- Supply Ability

- 2 Units Per Month

- Delivery Time

- 15 Days

- Sample Available

- No

- Sample Policy

- Sample costs shipping and taxes has to be paid by the buyer

- Main Export Market(s)

- Middle East, Africa

- Main Domestic Market

- All India

About Robust Construction Triple Compression Hydraulic Baling Press

A Triple Compression Baling Press is a specialized piece of industrial equipment designed to compact and densify various types of materials, such as scrap metal (ferrous and non-ferrous), waste paper, plastic, and other recyclable or discarded items, into high-density bales. The "triple compression" refers to its unique operational mechanism, which applies pressure from three different directions typically top, side, and end to achieve a significantly higher compaction ratio compared to single or double compression presses.

Key Features and Principles:

- Three-Dimensional Compaction: Unlike simpler balers that might only press from one or two sides, a triple compression baler utilizes a sequence of pressing actions.

- Primary Compression (e.g., Main Ram/Lid Compaction): Material is initially loaded into the charging box, and a main ram or a top-closing lid compresses the material downwards, reducing its initial volume.

- Secondary Compression (e.g., Side Ram): Once the primary compression is complete, a side ram (or rams) moves in to compress the material horizontally, further increasing its density and shaping the bale.

- Tertiary Compression (e.g., Ejection Ram/End Compaction): Finally, an ejection ram or an end-compression ram applies pressure from the third direction, pushing the fully compacted material out of the baling chamber as a finished bale. This final push also contributes to the extreme density.

- High Density Bales: The primary advantage of triple compression is the production of extremely dense and uniformly shaped bales. This densification minimizes bale volume, leading to:

- Reduced Storage Space: More material can be stored in a smaller footprint.

- Lower Transportation Costs: More weight can be loaded per truck/container, optimizing logistics.

- Improved Handling: Denser bales are often more stable and easier to manage with forklifts or other machinery.

- Enhanced Melting Efficiency (for metals): For scrap metal, higher density bales melt more efficiently in furnaces, reducing energy consumption and increasing yield.

- Robust Construction: These presses are built to withstand immense forces. They typically feature heavy-duty steel frames, reinforced chambers, and powerful hydraulic cylinders.

- Hydraulic System: A sophisticated hydraulic system powers the rams, providing the massive force required for compression. This includes large-capacity pumps, reservoirs, and control valves.

- Automated Operation: Many modern triple compression balers are highly automated, featuring programmable logic controllers (PLCs) for controlling the baling cycle, material feeding, and bale ejection. This can include automatic wire or strap tying mechanisms for securing the bales.

- Versatility: While often associated with scrap metal, they are also used for high-volume baling of other materials where extreme density is critical.

- Applications: Commonly found in:

- Scrap yards and metal recycling facilities

- Automotive shredder residue (ASR) processing

- Large-scale waste management and recycling centers

- Industrial manufacturing plants generating significant volumes of waste.

- Scrap yards and metal recycling facilities

In summary, a Triple Compression Baling Press represents the pinnacle of baling technology, offering unparalleled compaction capabilities for materials that benefit from extreme densification, ultimately leading to significant operational and economic advantages in recycling and waste management processes.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Triple Compression Baling Press Category

Triple Compression Baling Press With Turn Out Scrap Metal Baler

Price 1500000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Voltage : 380440 Volt (v)

Condition : New

Power Source : Hydraulic

Heavy Duty Metal Baler Press

Price 1250000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Voltage : 415 Volt (v)

Condition : New

Power Source : Hydraulic

Hydraulic Metal Baler Press with PLC Control

Price 1800000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Voltage : 415 Volt (v)

Condition : New

Power Source : Hydraulic

Triple Compression Baling Press with Hopper

Price 1400000.0 INR / Unit

Minimum Order Quantity : 1 Unit

Usage : Industrial

Voltage : 440 Volt (v)

Condition : New

Power Source : Hydraulic

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS